Zeus

#127

Thread Starter

I used epoxy mixed with microballons. I think it was a bit thick and didn't flow as well as I would have liked. I've got the other half in the press with mostly PVA. We will see what the difference is.

Last edited by RodneyFord; 05-26-2018 at 02:14 AM.

#130

Thread Starter

Well I haven't actually used it for sheeting, but of course I am aware of it as an option. Usually I dope the inside of the balsa, apply epoxy and vacuum bag them to the cores. This is simple light and strong. However I do like to try different systems and this is the latest experiment. Tomorrow we will see how this variation turns out.

#131

I know kevlar is very popular fabric to use. From my limited experience with kevlar it seems the epoxy does not really bond with the kevlar. the epoxy only seems to encapsulate it. What is your experience? What is the reasoning to use kevlar instead of another product? I'm not bashing your choice, I'm just trying to understand why kevlar was chosen over another cloth.

Thanks! Ken

Thanks! Ken

#132

Thread Starter

I know kevlar is very popular fabric to use. From my limited experience with kevlar it seems the epoxy does not really bond with the kevlar. the epoxy only seems to encapsulate it. What is your experience? What is the reasoning to use kevlar instead of another product? I'm not bashing your choice, I'm just trying to understand why kevlar was chosen over another cloth.

Thanks! Ken

Thanks! Ken

I have made a few full kevlar fuselages and my experience is that it is strong and light. I have not experienced any problems with the resin fabric matrix. The issues I have had are just the usual ones, you need aramid scissors and it can't be sanded easily. Fully wetting it out is an issue too as it doesn't take the wet look of glass.

I suppose I could have used the 80 gm carbon instead but it is very expensive and there is the RF issue so I just used it for local reinforcement. I could make it neater and also improve the resin to fabric ratio. All in all this would have to be one of my best fuselages

Last edited by RodneyFord; 05-26-2018 at 05:05 PM.

#133

Thread Starter

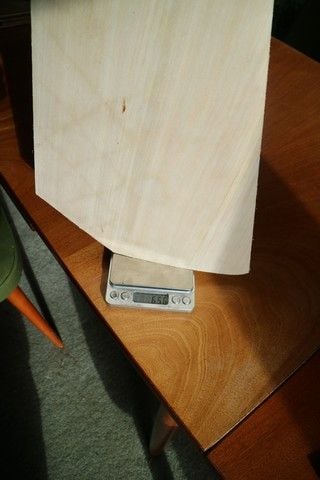

The second stab half out of the press. It weighs 78gm but feels damp and you can see where the glue is. I expect it to lose a fair bit of weight as it drys properly. I cant see it being a lot lighter than the first half though.

#141

Thread Starter

Working on the engine mount while waiting for the epoxy on the tail donuts to cure.

16mm brass tube to cut 20mm thick rubber.

Into the lathe to cut the 4mm hole in the middle.

Cut them in half for 16mmx10mm bushes.

16mm brass tube to cut 20mm thick rubber.

Into the lathe to cut the 4mm hole in the middle.

Cut them in half for 16mmx10mm bushes.

#142

Thread Starter

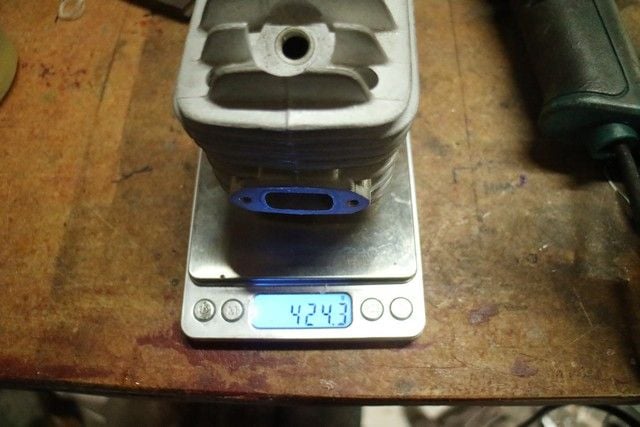

I've taken the head off the DA50 to lighten it. DA says they take off 4 oz but I doubt whether I can.

Lathe work done next it will go on the mill.

I had to make a fixture to hold the cylinder for machining.

#146

Thread Starter

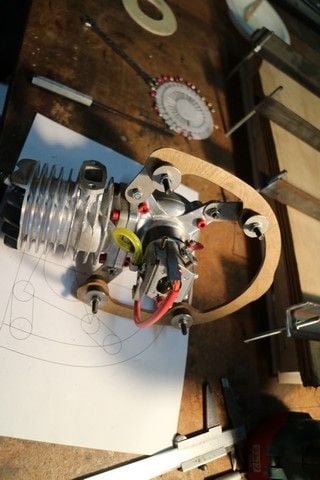

Cheers Jim. Working on the engine mount.

Mock up of engine mount to see if it works.

Tilting the engine 10 degrees for exhaust clearance. There is lots of room in there though.

Mock up of engine mount to see if it works.

Tilting the engine 10 degrees for exhaust clearance. There is lots of room in there though.

#147

Thread Starter

Installed the anti rotation pin for the tail planes.

It is difficult to get the donuts in for the pin.

Long tweezers from an aquarium shop makes it easy though.

#150

Thread Starter

Made titanium washers for the engine mount.

Assembled the engine mount to check the fit.

I will replace the steel screws with high tensile aluminium ones.